Far more than just an alternative: molybdenum is unique.

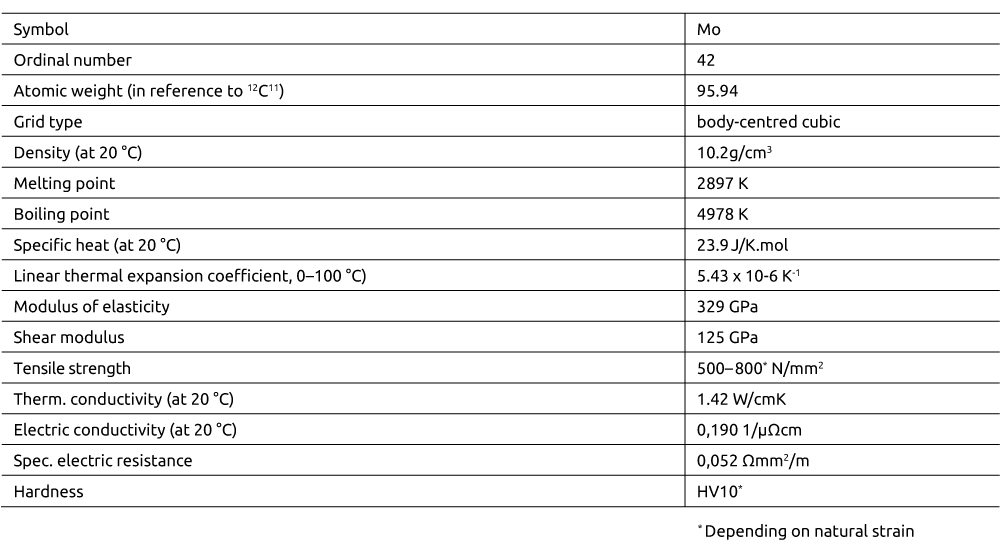

Molybdenum as a metal is not quite as well known as tungsten. It has a lower melting point but is nevertheless commonly used for the production of illuminants, in the glass industry, for heating elements and in furnace construction. Molybdenum is a 5th period transition metal. The high-strength, tough and hard metal is a glossy, silvery white. It has the highest melting point of all 5th period elements. While it is a very hard metal, it is softer and more ductile than tungsten. Just like its big brother tungsten, it is not attacked by reducing acids (even hydrofluoric acid). Oxidising acids such as hot, concentrated sulphuric acid, nitric acid or nitrohydrochloric acid (aqua regia) lead to high removal rates. Molybdenum is also not resistant to oxidising molten alkalis.Physical properties of molybdenum:

Chemical properties of molybdenum:

TZM

TZM with a composition of 0.5%Ti, 0.08%Zr, 0.03%C and Mo is among the most commonly used molybdenum alloys. It is produced either in a powder metallurgy or arc melting process, has a higher recrystallisation temperature and higher strength compared to pure molybdenum, and is readily deformable even at room temperature. These effects are due to mixed crystal formation between Mo and Ti as well as the precipitation of ZrC as a dispersoid.

Thanks to the special material properties, the application possibilities for TZM are numerous (for instance vacuum furnaces, X-ray technology and more)

TZM with a composition of 0.5%Ti, 0.08%Zr, 0.03%C and Mo is among the most commonly used molybdenum alloys. It is produced either in a powder metallurgy or arc melting process, has a higher recrystallisation temperature and higher strength compared to pure molybdenum, and is readily deformable even at room temperature. These effects are due to mixed crystal formation between Mo and Ti as well as the precipitation of ZrC as a dispersoid.

Thanks to the special material properties, the application possibilities for TZM are numerous (for instance vacuum furnaces, X-ray technology and more)

- High thermal conductivity

- Low vapour pressure

- Good resistance against corrosion

- Various mechanical processing options

MLa

The mechanical properties of molybdenum can be effectively boosted through doping with 0.3-0.7 percent by weight of finely distributed lanthanum oxide particles. Forming a staple fibre structure tremendously increases the strength, ductility, recrystallisation temperature and creep resistance.

MLa can be used at temperatures up to 1800°C. Typical applications include heating conductors, lighting technology, sintering boats and furnace construction.

The mechanical properties of molybdenum can be effectively boosted through doping with 0.3-0.7 percent by weight of finely distributed lanthanum oxide particles. Forming a staple fibre structure tremendously increases the strength, ductility, recrystallisation temperature and creep resistance.

MLa can be used at temperatures up to 1800°C. Typical applications include heating conductors, lighting technology, sintering boats and furnace construction.