Tungsten & tungsten alloys

Materials with the finest properties

However high the hurdle, our refined tungsten materials are up to the challenge.

However high the hurdle, our refined tungsten materials are up to the challenge.

Tungsten is a metal of extremely high thermal resistance and density. It has:

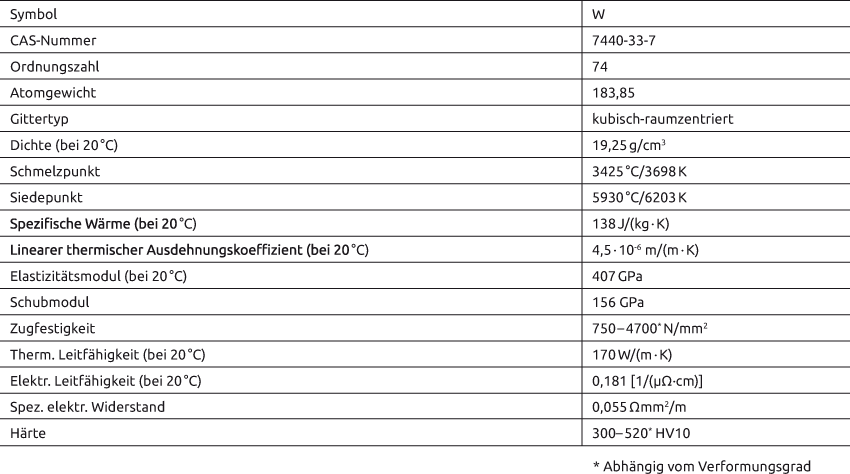

Temperatures similar to those on the surface of the sun (approx. 5,900 °C) are required to boil tungsten. With a density of 19.28 g/cm³, tungsten is also among the heaviest metals which explains why it is for specific mass balancing among other things. Tungsten takes eighth place in the electrical conductivity ranking. This means it has about 31% of the electrical conductivity of copper.

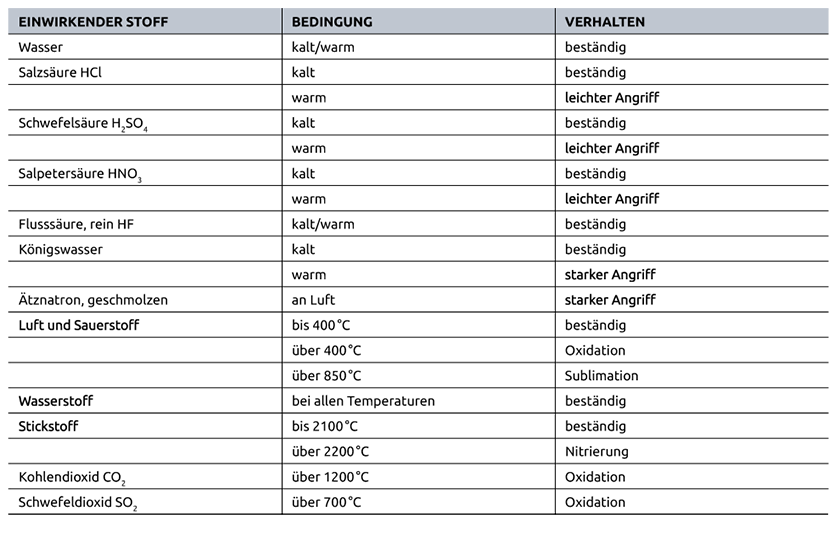

Tungsten is also a special metal in terms of its chemistry. It is extraordinarily resistant to air exposure at room temperature. Only at high temperatures does it gradually burn, forming tungsten (VI) trioxide “(WO3)”. It is impervious to most acids and bases. Mineral acids, hydrofluoric acid and even nitrohydrochloric acid (aqua regia) only attack the metal slowly. It does however dissolve quickly in a mixture of nitric and hydrofluoric acid.

Wolfram (Englisch: Tungsten) ist ein äußerst widerstandsfähiges Schwermetall, das sich durch seine außergewöhnliche Härte, hohe Dichte und den höchsten Schmelzpunkt aller Metalle auszeichnet. Diese Eigenschaften machen es zu einem der gefragtesten und beständigsten Werkstoffe in der modernen Industrie. Das grauglänzende Metall gilt in Bereichen als unverzichtbar, in denen Bedingungen herrschen, die nach hitzebeständigem und verschleißfestem Material verlangen.

Wolfram wird hauptsächlich aus Wolframerzen gewonnen. Zu den wichtigsten gehören Scheelit (Calcium-Wolframat) und Wolframit (Eisen-Mangan-Wolframat). Die Erze enthalten Wolfram in geringer Konzentration, weshalb sie in aufwendigen Prozessen chemisch und mechanisch aufbereitet werden, um das reine Metall zu extrahieren.

Die Bedeutung von Wolfram und Wolframlegierungen für verschiedene Industrien

Wolfram und seine Legierungen kommen in spezialisierten Branchen zum Einsatz, die sehr hohe Anforderungen an Materialeigenschaften stellen. In der Schweißtechnik garantieren WIG-Elektroden stabile Schweißnähte bei hochreinen Verbindungen wie Titan oder Aluminium-Legierungen. Unsere Produkte WS2, INOSTAR® oder ALUSTAR® sind mit ihrer Hitze- und Verschleißbeständigkeit in der Luft- und Raumfahrt sowie der Medizintechnik unverzichtbar. Aufgrund ihrer Langlebigkeit und Belastbarkeit bieten sie sichere Lösungen für Hochtemperaturprozesse.

Auch in der Elektronik, dem Werkzeugbau und der Pharmaindustrie kommen spezialisierte Produkte wie TUNGSTIT® und TRIAMET® zum Einsatz. Anpassbare Leitfähigkeit und Dichte sind in streng regulierten Produktionsumgebungen wichtig, wie sie bei der Sterilisation und der Herstellung von pharmazeutischen Geräten gefordert werden.

Density: 18.0-19.25 g/cm³ (depending on the degree of deformation)

Strength: for a diameter of 1.0-1.99 mm > 1,500-2,200 MPa

for a diameter of 2.0-3.2 mm >1,300-2,000 MPa

Expansion: <6%

Recrystallisation properties:

Specific electric resistance:

Thermal conductivity at 293°K / 174 W/m-K

Temperature coefficient: 273–373 K 4.5 · 10-6 K-1

Surface: ground, drawn (black/cleaned), hammered, turned, milled and eroded available

Heat treatment: May be annealed or unannealed