TIG welding electrodes

Whatever the application, we ensure reliable stability while welding

Whatever the application, we ensure reliable stability while welding

We develop 100% of our TIG welding electrodes in Germany, all manufactured from tungsten powder. Our wide-ranging product scope includes in-house innovation alongside DIN-standard electrodes.

All this is non-negotiable:

We are the only European manufacturing company authorised to produce tungsten-thorium. So over and above radiation-free alternatives, we also offer the only premium-quality WTh electrodes.

For these applications: TIG, plasma applications, lighting and illumination technology

We pioneered development that made our name and won us popularity worldwide. No other supplier can offer a correct 2% by weight rare earth blend. And its positive properties make WS2® the only serious WTh alternative readily copied by other manufacturers.

For these applications: TIG, plasma applications, lighting and illumination technology

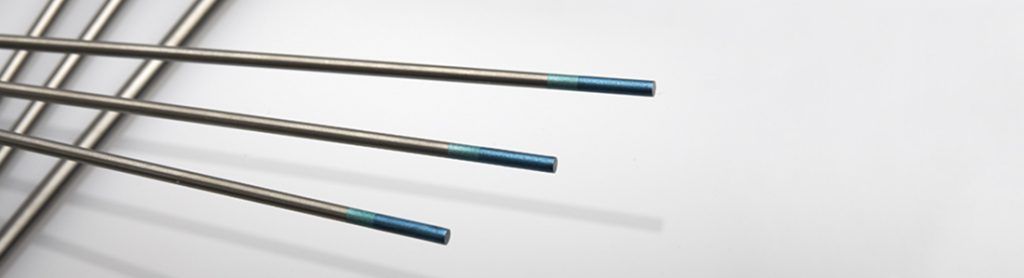

Our latest top development since 2013: the Inostar® alloy. It contains up to 2 percent by weight of a rare earth blend, further improving the already excellent properties of the WS2 alloy:

We consider its key applications to include the high-purity bonds so crucial for medicine, pharmaceuticals and food technology. You can weld even sensitive metals like titanium seamlessly with the INOSTAR® alloy.

Product info: Inostar (PDF)

For these applications: TIG welding of aluminium alloys

Alustar® is an alloy developed especially for welding aluminium. Its composition extends the service life and improves arc focusing. Perfect dome formation and a reduction of post-processing are positive side effects.

Product info: Alustar (PDF)

For these applications: TIG welding, plasma applications

“Their red” WTh20 remains a go-to even now, for many welders in Europe and Asia. And this despite the dangers that slightly radioactive electrodes may present. Up to 4 percent by weight of thorium dioxide is added to alloys of the WTh type during production. The higher the oxide content, the more ignitable the substance, compared to pure tungsten.

Thoriated tungsten is used wherever a stable electron exit is essential: in plasma spraying, electron beam sources and also welding (see above).

The electrode also responds “positively” to high currents. But it must be handled with special caution: Vapours or fine dust produced during welding or while resharpening the electrode tip can be harmful to health. This makes it all the more crucial to employ the right safety measures (vacuum cleaning).

We are the only manufacturing company in Europe with approval to produce tungsten-thorium. In other words, no other company produces WTh electrodes that are 100% compliant with German quality standards.

For these applications: TIG, plasma applications, resistance welding

When producing WP electrodes, we only use tungsten powder with minimum 99.95% purity and zero additional alloying elements. The powder is briefly mixed, filled into a mould and compacted. It is then sintered into a rod and shaped into its final form by rotary swaging, drawing, grinding and so on. The high electron work function (4.5 eV), explains why the temperature increases at the tip and the microstructure recrystallises. The service life is comparatively short. WP is generally used only for AC welding, for example on aluminium and magnesium alloys.

For these applications: TIG, plasma applications, resistance welding

Besides the WTh alloy, the WLa alloy offers the widest range of applications. Its lanthanum (III) oxide content, up to 2% by weight, opens up a very wide range of applications for this compound: Electrodes for TIG, orbital, plasma and resistance welding, and many more.

Another key rule of thumb: the higher the oxide content, the better the ignition of the electrode. And here too, its low alloy content makes the WLa10 electrode ideal for AC welding of aluminium and magnesium. No wonder then, that this alloy type is the preferred WTh20 replacement in Europe.

For these applications: TIG welding, resistance welding

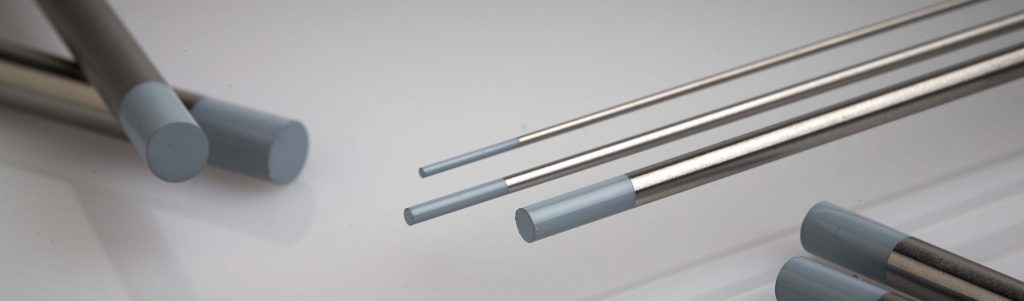

Many welders worldwide consider the grey WCe20 as the new “red one”. This alloy contains cerium (IV) oxide up to 2% by weight, which is why it is set to outrank the WTh material for TIG and plasma welding. The electrode type is universal in application and exhibits better ignition behaviour than thoriated electrodes.

For these applications: TIG welding (welding of Al and Mg alloys)

For the WZr alloy type, up to 0.8% by weight of zirconium oxide is added to the tungsten powder during production. The alloy is used almost exclusively for TIG electrodes: The low alloy content makes this material perfect when welding joints with seams that must be free of foreign materials. The alloy can also be used for the AC welding of aluminium and magnesium. Here it exhibits a more stable arc compared to WP.